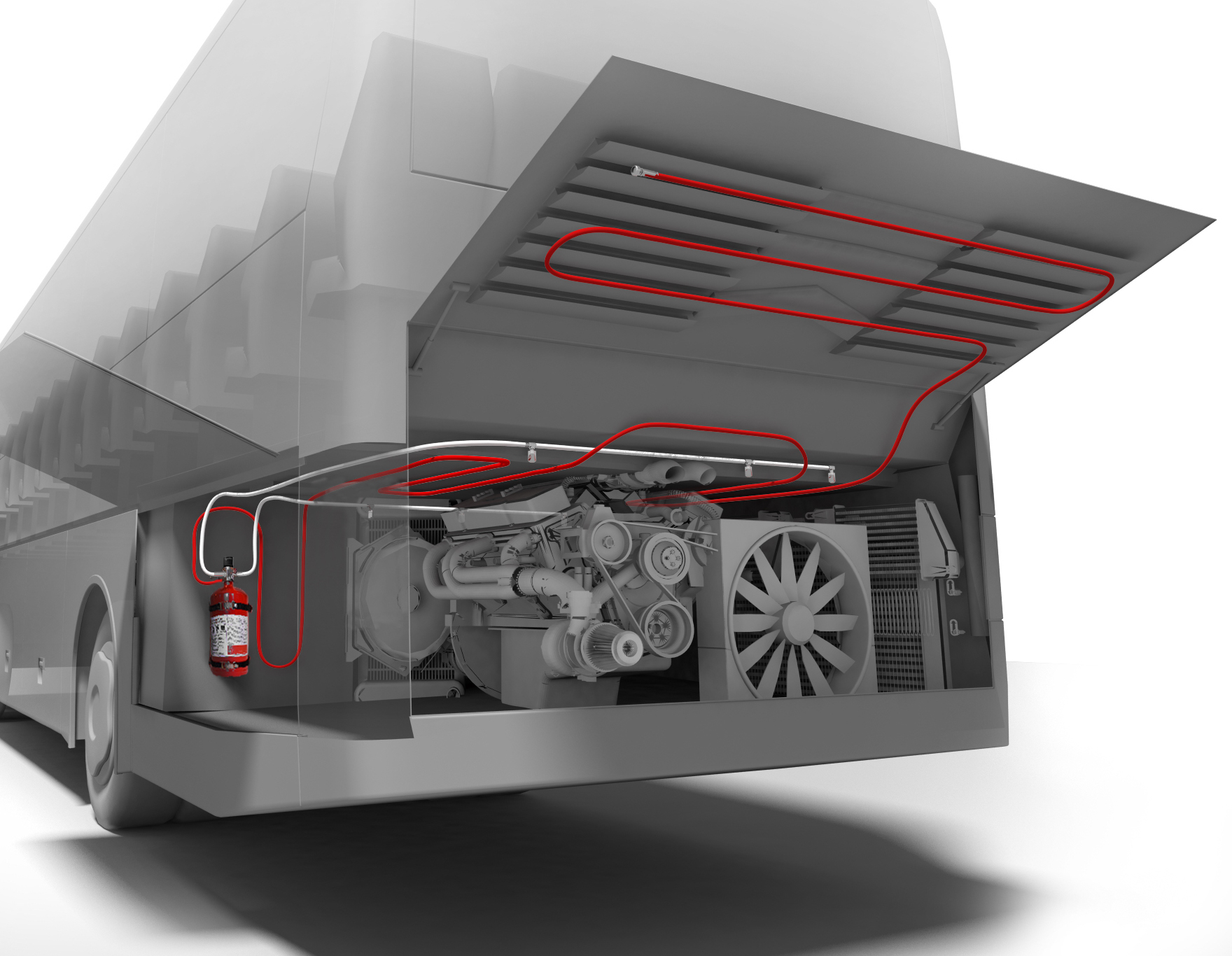

Bus Fire Suppression System

System offering

Universal and Variable

- The system is designed to be adapted to any type of bus. The system can be equipped with a number of additional components: signalling and control unit, pressure switch for additional operations, electric or pneumatic detection and manual start of extinguishing, etc.

Fully automatic

- The system does not require the driver to actuate. Even when the bus in parked in the yard without a driver inside the system can still protect the bus.

Visual indicators for the operator

- The system features an alarm panel mounted at the driver’s position. The alarm panel produces an audible as well as a red flashing LED light to signify the system has responded to a fire. While in standby mode a green light indicates the system is active and ready to operate.

Easy to Install and Maintain

- Starting from only 3 nozzles and high component flexibility the BlazeCut system allows for quick installation and minimal maintenance. The system is light weight so it can be installed and suspended over the risk areas with minimal fittings.

3 Year Warranty and Long Life

- Premium components and high reliability allows the BlazeCut system to be offered with a 3 year warranty.

High Efficiency

- Having quick discharge, consistent coverage and high extinguishing efficiency the BlazeCut system will extinguish the fire within 2 seconds on average from the commencement of activation. The extinguishing agent is suitable for diesel, petrol, LPG, CNG, hybrid and electric buses.

- Fast knock down against the flames

Independent of Electrical Supply

- The BlazeTube LOP detection system does not require electrical power and is always active and ready to respond to a fire.

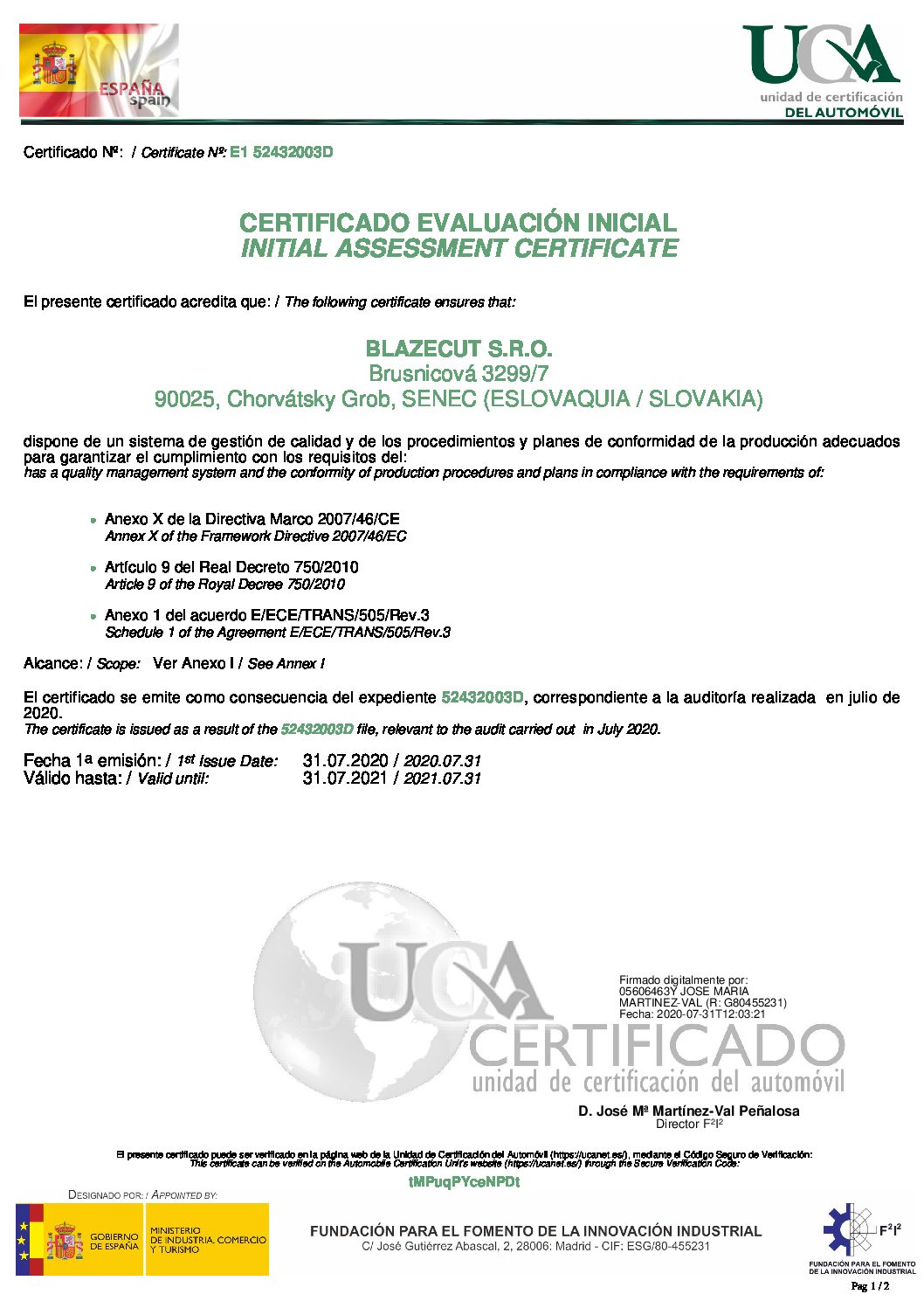

Certified System and Production

- UNECE R107, CE, ISO 9001: 2016, ISO 14001: 2016,AQAP 2110: 2016 and other certificates and tests are a guarantee of the highest product quality.

System Design Compliance

The BlazeCut Powder Fire suppression system for Buses requiring UNECE Regulation. No. 107 Compliance can feature the following options.

- System Monitoring using the BlazeCut Alarm Panel at the driver’s seat. The Alarm Panel monitors faults and will alert the driver in the event of a fire and when discharge occurs.

- BlazeTube or BlazeWire Detection using LOP or LHD technology for heat sensing.

- System operation can be selected as fully automatic, manual only or a combination of automatic and manual.

Approvals

BlazeCut has conducted all necessary testing and approvals to supply UNECE Regulation. No. 107 fire suppression systems to all bus manufacturers

Audit that Confirms a quality management system and the conformity of production procedures are in place.

Additional information and confirmation of testing processes.

Confirmation on successfully passing the R107 testing protocols

Watch the Fire Test

Test – High fire load with fan

This is the test for High fire load with fan which is one of 4 tests for approval. BlazeCut has conducted all necessary testing and approvals to supply UNECE Regulation. No. 107 fire suppression systems to all bus manufacturers. This test was conducted in a certified testing body.

System Components

Cylinder Valve

The Cylinder is supplied ready to install with the cylinder valve mounted. The cylinder valve can be pneumatic or electronic and is closed by a piston, which maintains the pressure in the cylinder. When a fire is detected the valve piston opens rapidly and immediately releases the powdered agent. The BlazeCut valve design allows the maximum flow of powdered agent, delivering it to the fire quickly and efficiently.

Cylinder

The Cylinder holds the powder which is used as the suppressant. There are a range of cylinder sizes which vary due to the amount of agent required. The cylinder comes with a cylinder bracket which can be rear or base mounted. Rubber lined secure banding is used to hold the cylinder while assisting with vibration control.

Alarm Panel

BlazeCut offer 2 alarm panels which can be used for the R107 compliant systems. The AAP200 is used in the Electronic heat detection system and has the added advantage of a manual discharge button that is installed at the drivers seat. Both the CAP200 and AAP200 panels monitor the systems integrity and highlight when the system is in either ‘Ok”, ‘Fault’, or ‘Fire’. While fire is flashing an audible alarm will also be initiated.

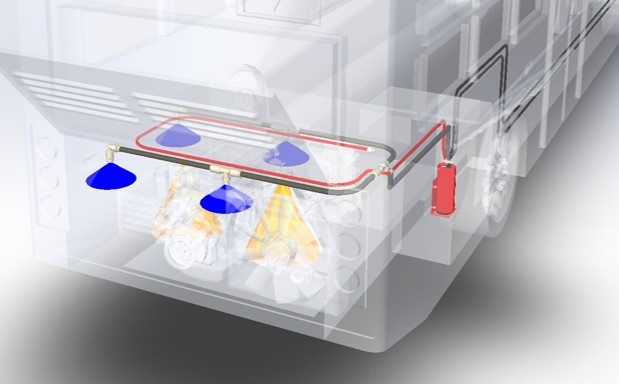

Detection

BlazeCut offers two distinctly different detection types, electronic BlazeWire and pneumatic BlazeTube. Both are manufacture to be a reliable and stable detection device when installed in the risk areas on the bus. The detection system and its location is paramount to the efficiency of the system to quickly react to fire.

Discharge Nozzles

The Stainless-steel nozzles are protected by a high temperature resistant cap which prevents dirt and debris blocking the nozzle. The nozzles have been designed to deliver a full conical spray pattern with either 120 or 160 degree option. Stainless steel brackets are also available as standard allowing for various mounting options.